The main function of blow-room is opening & cleaning of cotton fibre without any fibre damage. Also there is bend magnet for sorting of any metal.

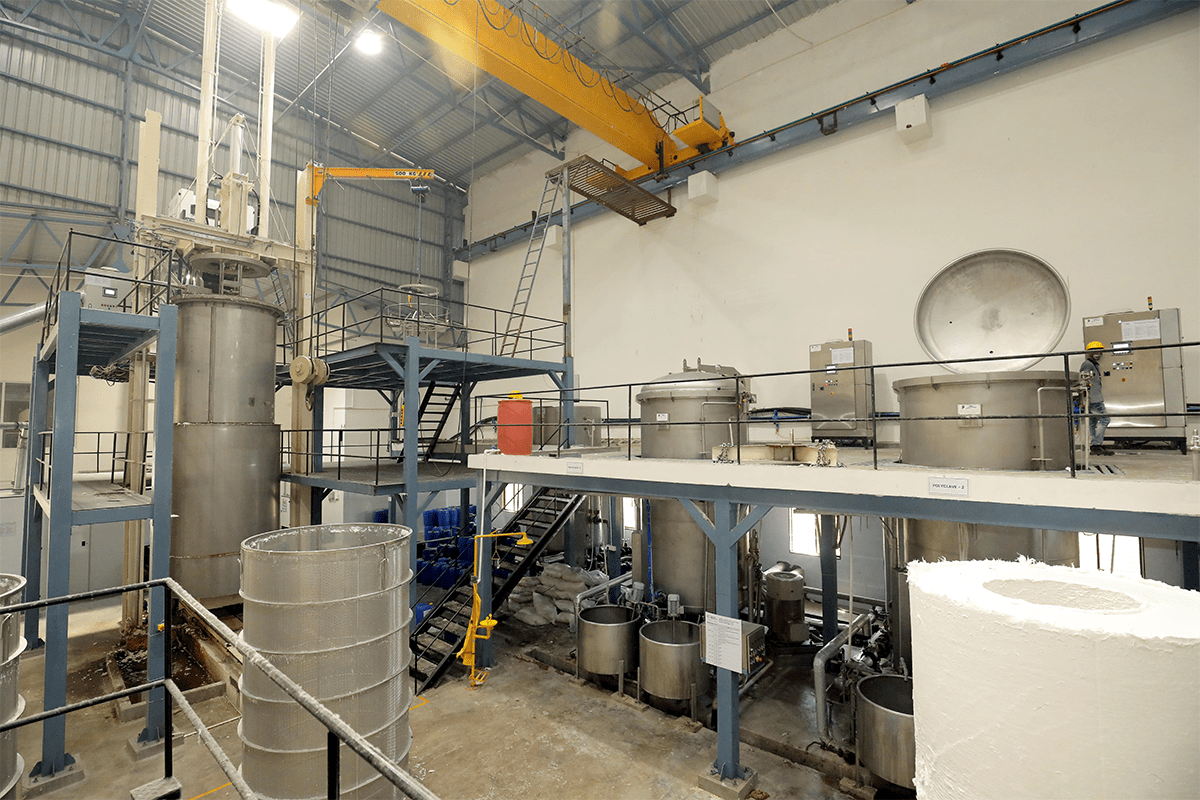

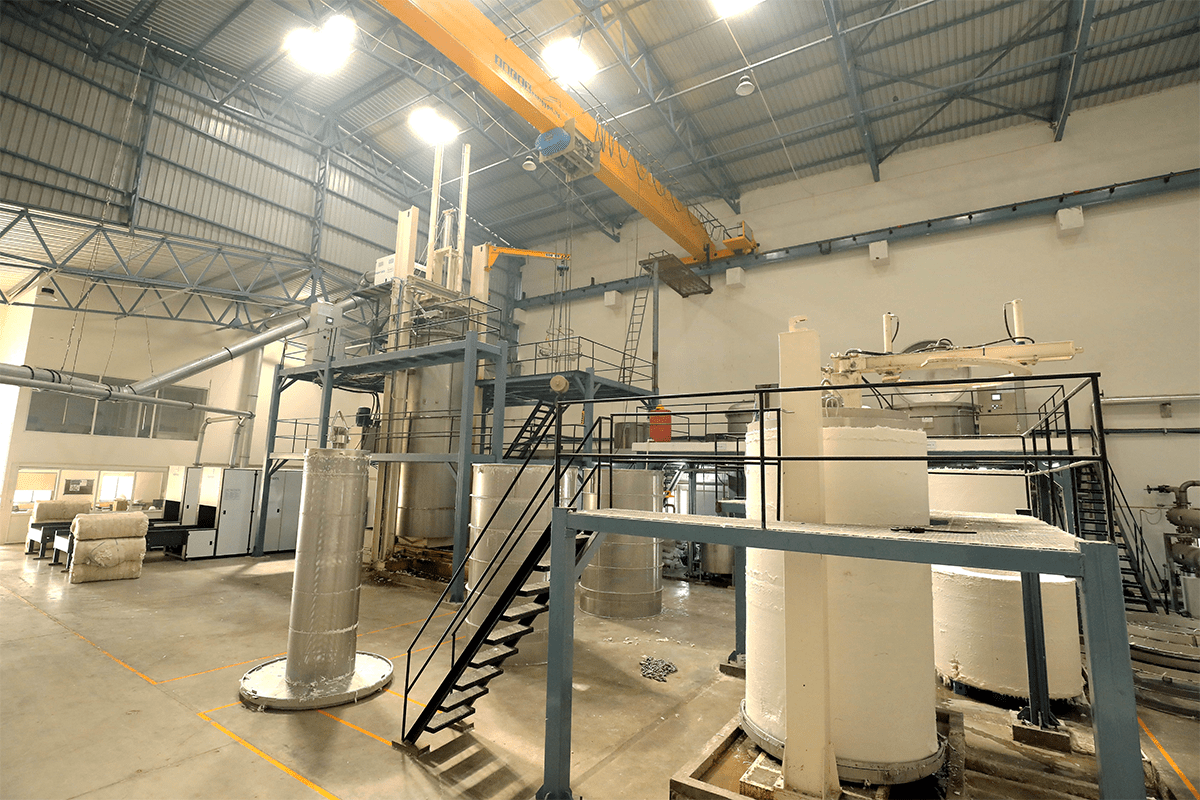

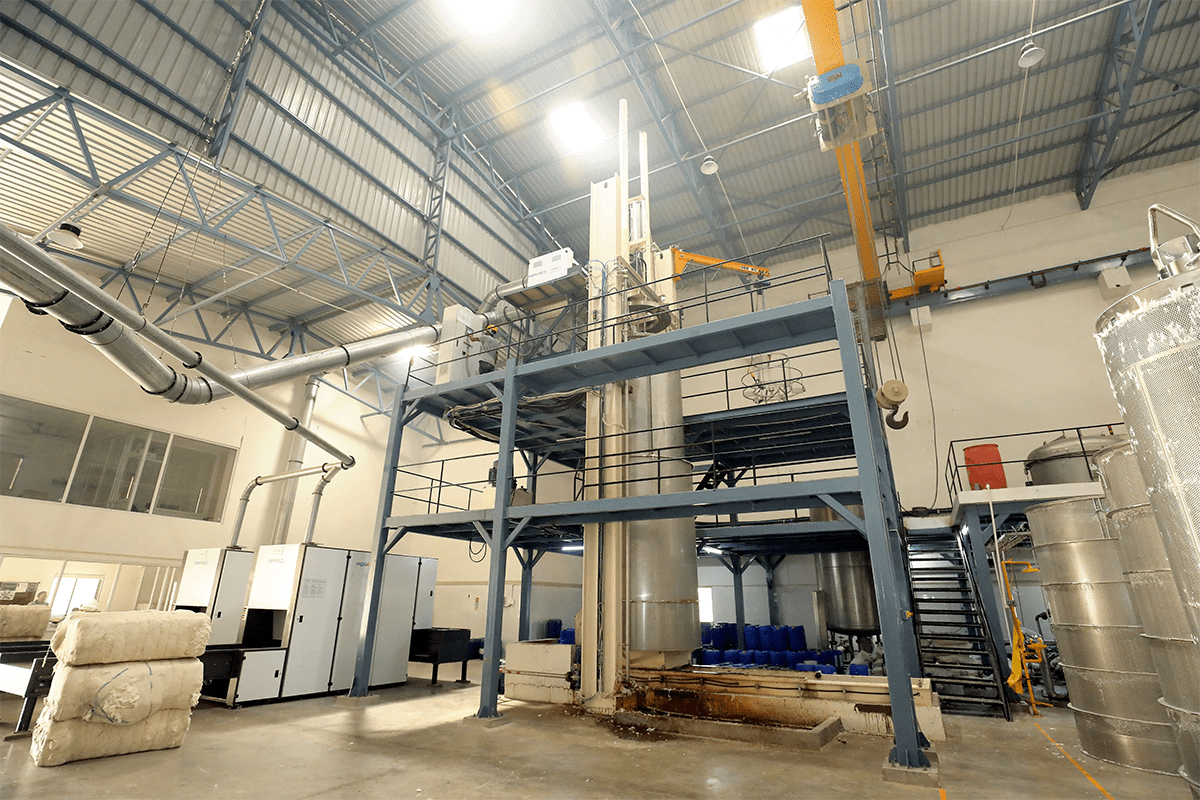

Polyclave designed for high density cotton cake. Batch size for one batch is equal to 1600KG. Eco-friendly process because very low MLR (Material Liquor Ratio). Less water & chemical consumption make it eco-friendly. Reduce burdens on ETP, RO & MEE.

Automatic cotton cake press machine with very high density cotton cake.

Automatic wet cake opener with double opening point. Cotton opened in this machine without any change in fibre properties.

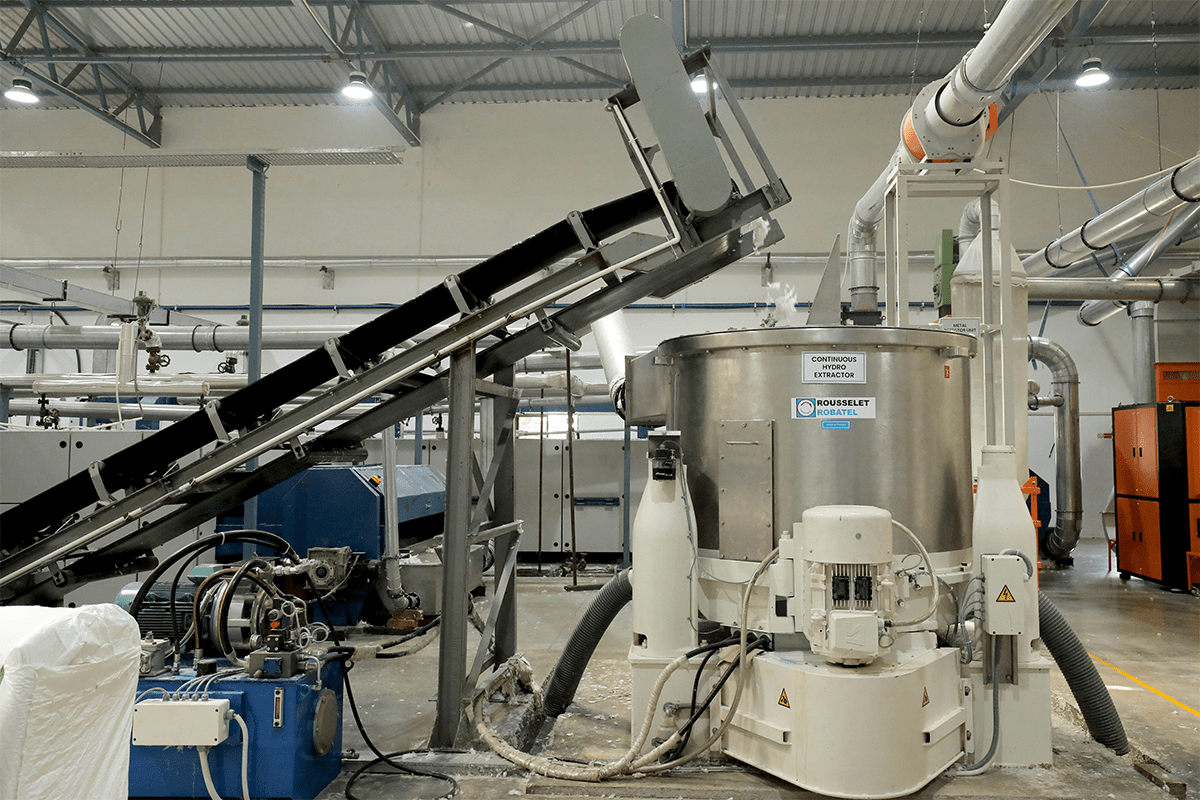

Uniform Cotton feeding after wet cake opener in hydro-extraction without any fibre touching. Due to fine opening of wet cotton hydro- extractor supply uniform cotton to dryer having consist moisture content.

Uniform Cotton feeding after hydro-extraction without any fibre touching. Due to Hydro-extractor after wet cake opener provide us the edge for consist Moisture content from Hydro-Extractor to dryer. Due to this there is always homogenous moisture percentage in final packed bale.

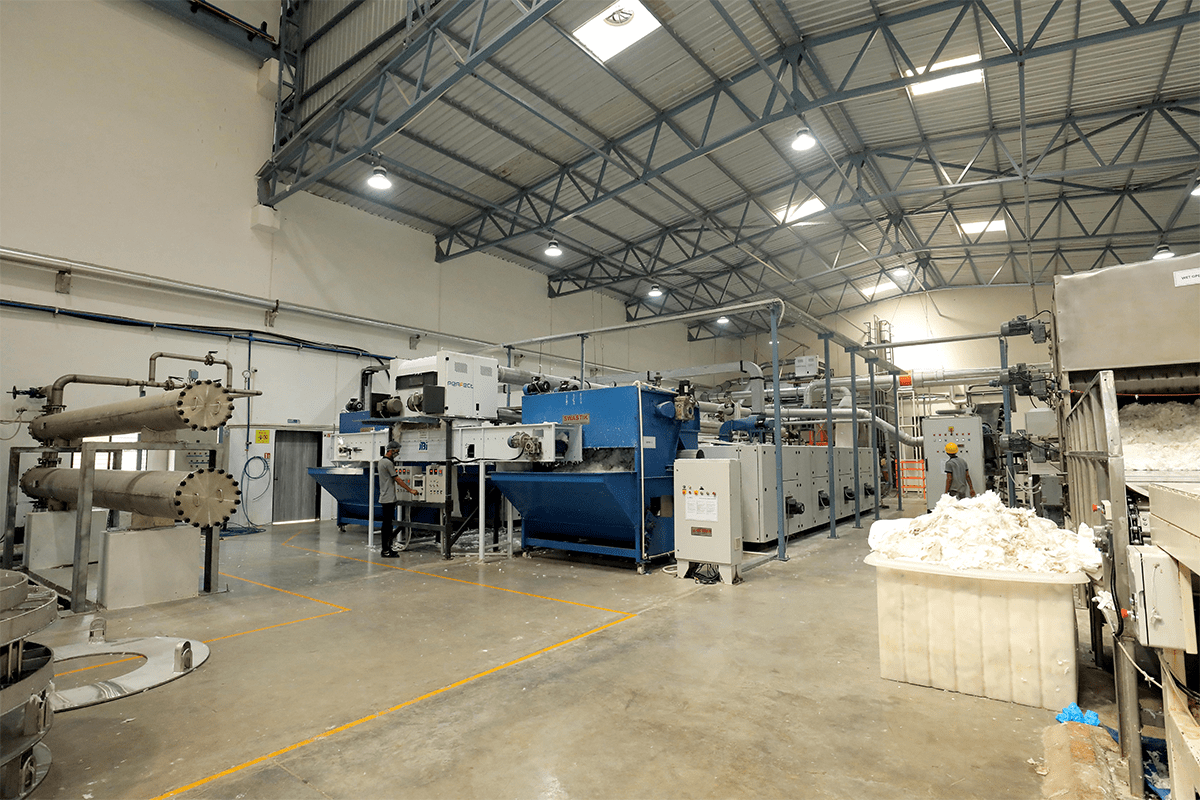

Fibre move from dryer to fine fibre opener through dect line. A metal detector installed in dect line from dryer to fine fibre opener. Fine opener helps to filter off impurities and mix the fibers. Highly efficient and minimized impairment of fiber. Enclosed design largely reducing the dust and flocks

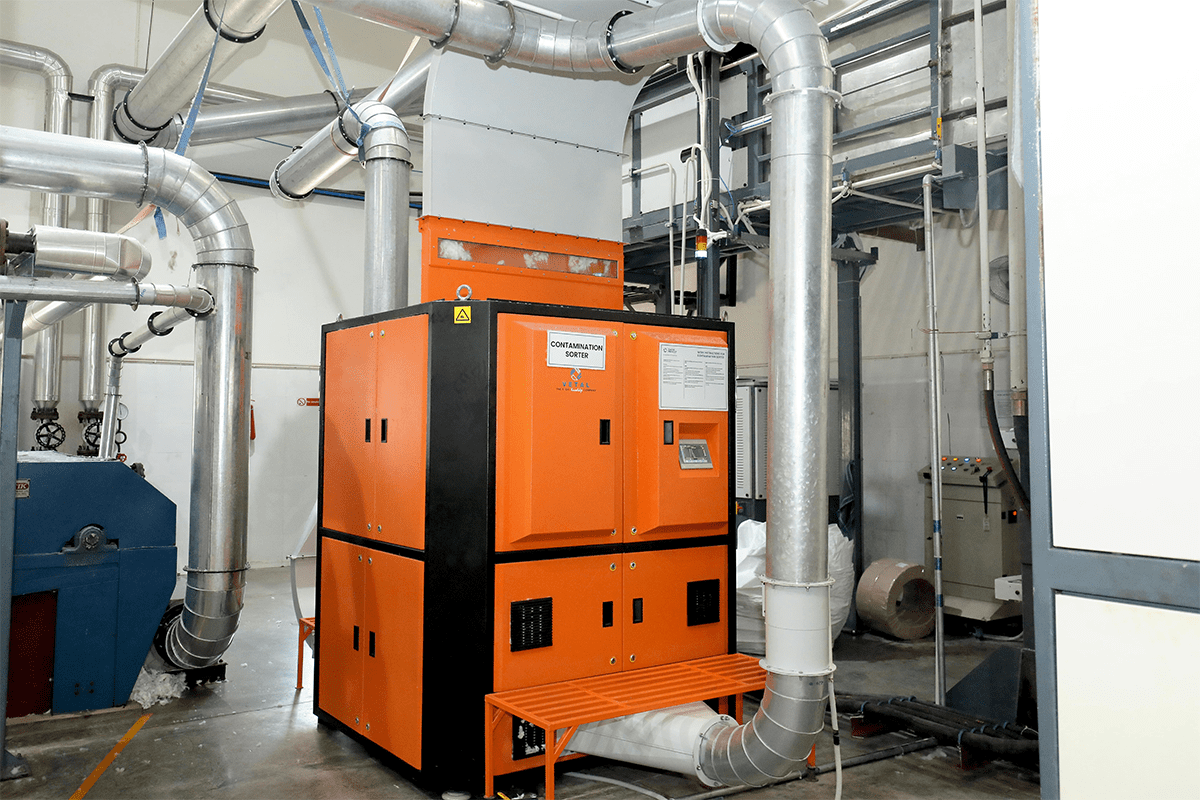

After fine fibre opening material pass through the contamination-sorter. Swan used latest version of contamination sorter with the cleaning efficiency is greater than 90%. Contamination sorter sort out all impurities i.e. PP, colour contamination, blackish & dirty particles & UV particles etc.

High Density Cake: Deliver a perfectly homogeneous cake formation with no splits or crack, and therefore no preferential flow paths.